Contact Us

Tel: 0755-29450980

Fax: 0755-29450871

E-mail: kingmag@king-mag.com.cn

Address: Building B, Bafang Zhigu, Junzibu Community, Guanlan Street Office, Longhua District, Shenzhen

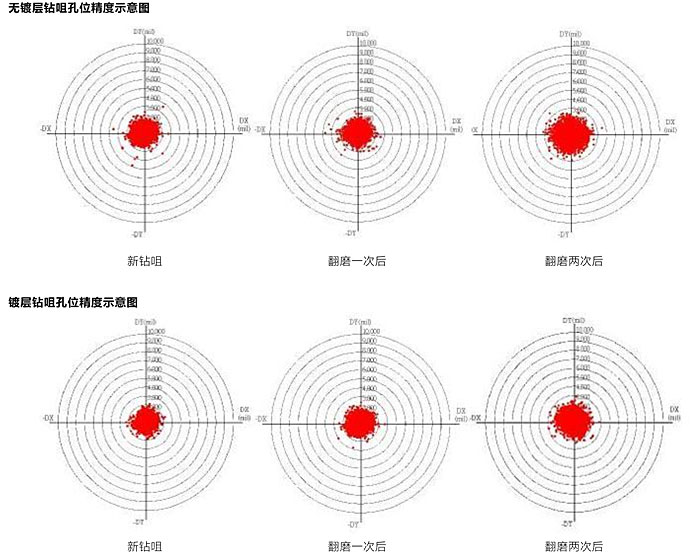

NGH nano-amorphous superhard gradient coating

Application range:

Main application areas

High-speed machining and difficult machining applications

Cold deformation mold

Extrusion and Stamping Dies

Wear parts

Injection injection mold

Micro drills and gong knives for PCB

Various specifications of drills and cutters

high temperature operation

Powder metallurgy and imprinting molds

Applications

Application on needle flat knitting machine

500-hour bench test results

project | Symptom |

NGH triangle not used | The triangular working face is severely worn, and the edge is chipped due to the high pressure, and the working noise is large |

Using the NGH Triangle | The triangular working surface has almost no wear, no chipping phenomenon, and low working noise |

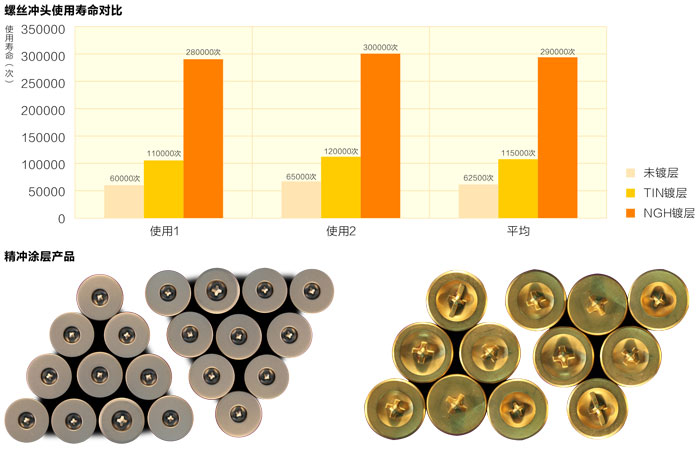

Application in fine blanking

Test parameters:

Punch material: M2 high speed steel Screw model: P30 type Wire material: 1018 wire Machine punching speed: 10000pcs/h

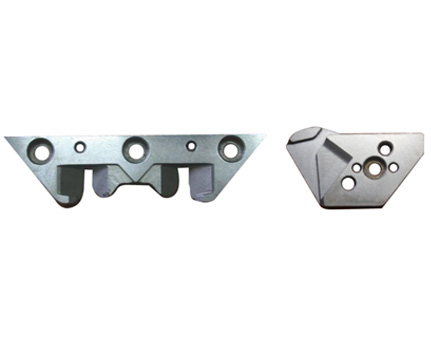

Application in stamping die

Test parameters:

Coating used: NGH coating Product material: CRS Die material: ASP23

Stamping Die Coated Products

Application in powder metallurgy mold

General powder metallurgy molds, especially magnet molds, have a service life of only about 1 month before NGH coating is used. After using NGH coating, the service life can be increased to about 3 to 4 months. Some powder metallurgy molds have a service life of only 100,000 to 200,000 times before using NGH coating. After using NGH coating, the service life is increased to 400,000 to 600,000 times, and the service life of some special powder metallurgy molds can be increased to 70 times. ~800,000 times, the effect is very obvious.

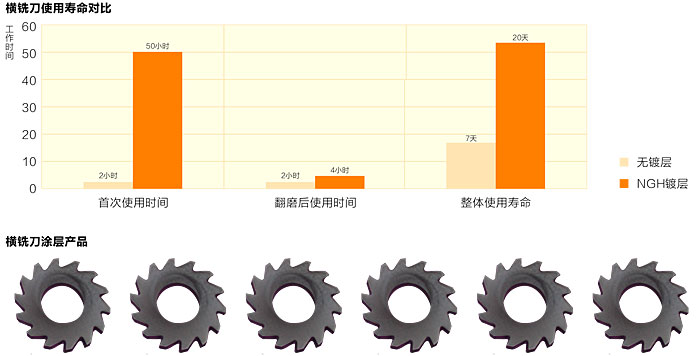

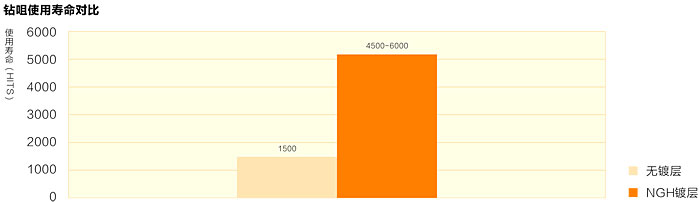

Application on PCB Micro-drill

Drilling parameters (S125KRPM)

Number of layers: 8 layers Thickness: 41~48mils Layup: L 2/9 copper thickness after electroplating is about 1.6mil

Drill diameter: 0.3mm Coating type: NGH nano gradient super hard coating

Drill diameter | category | Blocks per stack | Speed KRPM | Drop IPM | Speedback IPM | Lifetime HITS |

0.3mm | Uncoated | 3 | 110 | 80 | 1000 | 1500 |

Coated | 3 | 110 | 80 | 1000 | 4500/6000 |

After comparison test:

After drilling 6000 holes of the coated drill tip, the positions of the holes are all within the range of 3 mil. Due to the serious collapse of the ordinary drill tip, some holes exceed the range of 3 mil, which confirms the drilling accuracy of the drill tip after NGH coating treatment. Better than ordinary uncoated drill bits;

From the drilling test situation, when the drilling life of the coated micro-drill is increased by more than 3 times, the drilling quality fully meets the requirements (the CPK value of the hole position accuracy is less than 3 mil, the CPK value is greater than 1.33, the hole wall roughness is less than 1.2 mil, and the hole wall nail head is less than 1.5 times);

The use of NGH-1 type coating can effectively save more than 30% of the processing cost of the drill bit. At the same time, because the effective use time of the micro-drill is greatly extended, it reduces a lot of downtime for drilling and replacement, directly improves the production efficiency, and brings obvious benefits to users. income.

PCB micro-drill coating products

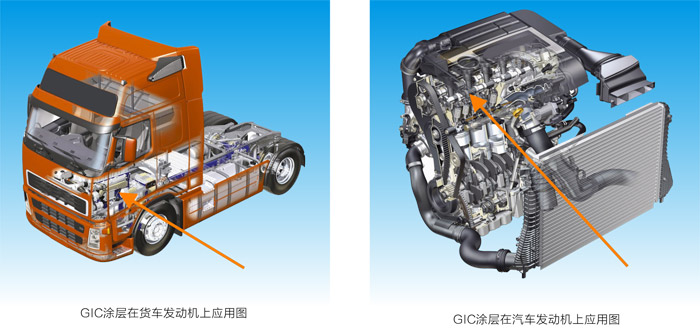

GIC nano-amorphous self-lubricating coating

Scope of application

Automotive Engines & Spare Parts Cutting Tools & Moulds Easy Wear Parts for Machinery Oil-Free Lubricating Spare Parts for Textile Industry

Moving parts of equipment operating in wet environments Parts for the food industry

Rain and snow fields Parts for die-forming equipment Parts requiring a low coefficient of friction

Applications

Applications in the automotive industry

Plunger bench test for fuel injection system applications

project | Test category | |

1500 hours plunger bench test | 300 vehicle tests | |

With GIC coating | There is no problem in the test, the matching clearance is good, and the operation is normal | 1% wear does not occur within the set range |

No GIC coating | Parts are often worn during the test, and the fitting clearance is poor | There is a 3% chance that accessories will be unavailable due to wear and tear |

Tappet bench experiment of engine system

project | 500 hours bench test |

With GIC coating | The end face wears evenly, the parts have no notch, and the end face roughness is about 0.3 |

No GIC coating | The end face is unevenly worn, some parts are notched, and the end face roughness is about 0.5 |

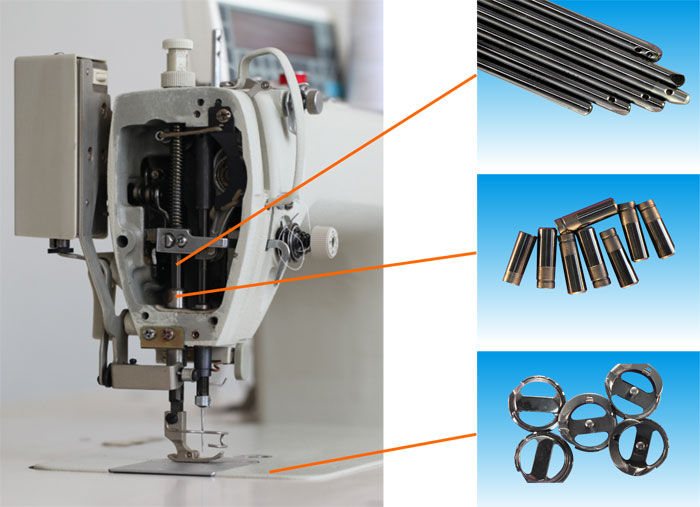

At the same time of the rapid development of the high-speed sewing machine industry, the problem of oil leakage and wear resistance has become a bottleneck restricting the development of the industry. The application of GIC coating on high-speed industrial sewing machine products effectively solves this problem and realizes oil-free lubrication and super wear resistance. dual performance.

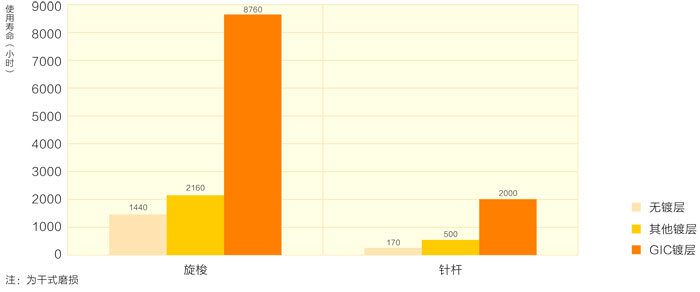

Application comparison of sewing hook and needle bar

Other Sewing Machine Coated Parts

MoST nano-amorphous self-lubricating coating

Scope of application

Precision products requiring reduced wear

Wear parts

Vacuum Fitting and Aerospace Fitting Applications

Precision products requiring a low coefficient of friction

dry machining tool

stamping die

forming mold

Forming tools and dies

Applications

decorative coating

Features

The combination of magnetron sputtering and multi-arc sputtering technology can produce high-quality films with rich colors, including but not limited to; IP chrome, IP gold, IP tint, IP brown, IP titanium, IP imitation gold , IP black, IP champagne, etc.

Under the two physical deposition methods, the film layer and the substrate can easily form a diffusion layer, and the film layer has good adhesion;

The incident particle energy is high, so the hardness of the film layer is high, and it has high wear resistance and scratch resistance;

The film layer has high smoothness and is not easy to stick to fingerprints;

Good corrosion resistance of film layer

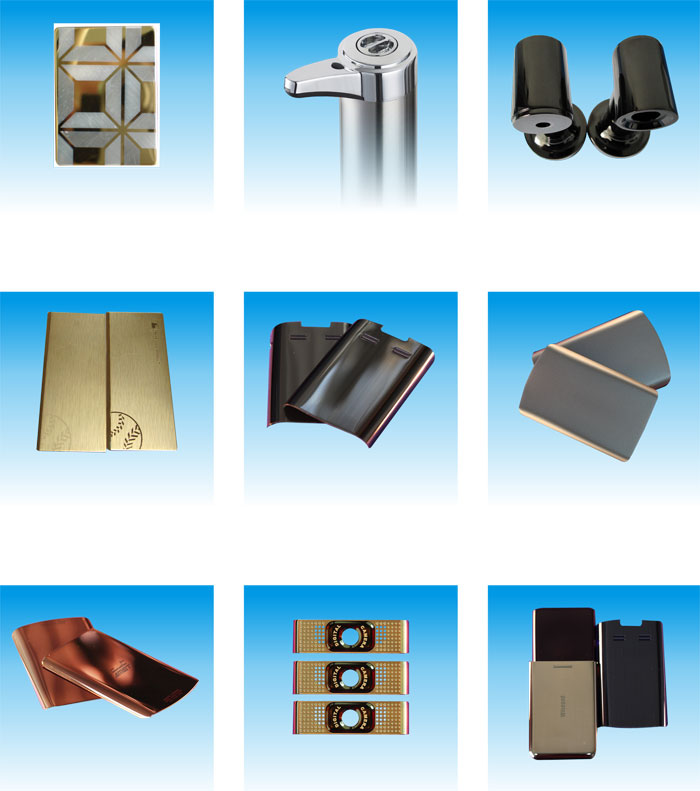

Coating types and application range

Type of coating | Plating name | Application field |

decorative coating | TiN, ZrN, gold series | Various types of blades, tableware, locks, bathroom, hardware sanitary ware, ceramics, glass and other hardware parts |

TiC, CrC black series | Watches and clocks, mobile phones, digital product shells, lighting bathrooms, spectacle frames and other hardware products | |

TiCN, TiAlN brown color | Watches and clocks, mobile phones, digital product shells, lighting bathrooms, spectacle frames and other hardware products |