Contact Us

Tel: 0755-29450980

Fax: 0755-29450871

E-mail: kingmag@king-mag.com.cn

Address: Building B, Bafang Zhigu, Junzibu Community, Guanlan Street Office, Longhua District, Shenzhen

Testing Equipment

Under the guidance of the system operation concept, the company continuously designs and develops relevant testing equipment to provide scientific and necessary testing methods for quality improvement.

MSIP coating performance testing equipment

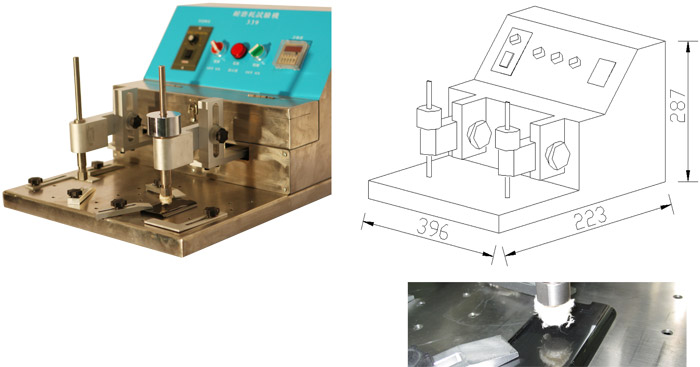

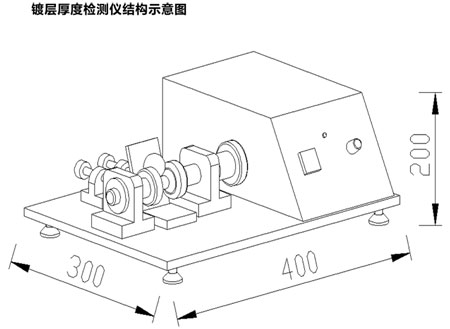

Coating thickness testing equipment

Equipment introduction

The coating thickness detector is mainly used to measure the thickness of various thin film materials.

Performance parameter table

| Numbering | project | technical parameter |

1 | name | Coating thickness detector |

2 | model | POD-1 |

3 | Equipment structure | |

3.1 | Dimensions | 400 (L )mm×300 (W)mm×200 (H) mm |

3.2 | motor | T.W.T motor, model: 41K 25RGN-C |

3.3 | speed controller | T.W.T Speed Controller, |

4 | Design Powered | AC 220V±5%,50HZ,100VA |

5 | Environmental requirements | Temperature:<40℃; Humidity: <80%RH |

6 | grinding ball | Material: chrome steel ball, Φ30mm |

7 | Abrasives | Diamond paste, grit: W0.5 |

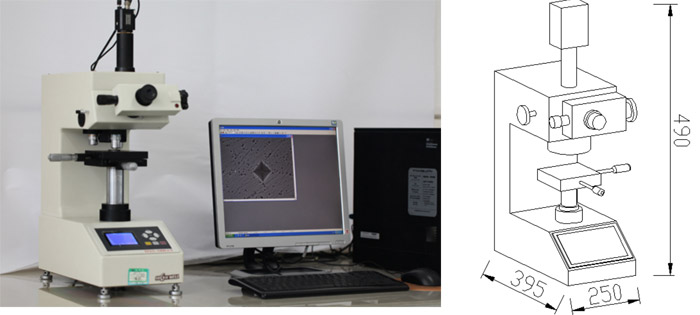

Coating hardness testing equipment

Equipment introduction: Coating hardness tester is mainly used to measure the microhardness of various thin film materials.

Structure diagram of coating acidity detector

Performance parameter table

| Numbering | project | technical parameter |

1 | name | Coating hardness tester |

2 | model | HXS-1000A |

3 | Equipment structure | |

3.1 | Dimensions | 395(L)×250(W)×490(H)mm |

3.2 | Indenter | Vickers (HV) indenter |

3.3 | Stage | Size: 110×110mm, Movement: 25mm, Minimum Movement: 0.01mm |

4 | measuring system | |

4.1 | Test load | 10、25、50、100、200、300、500、1000 |

4.2 | Loading method | Direct digital control, automatic loading and unloading of test loads |

4.3 | Test force holding time | 1-99 seconds |

4.4 | Indenter Objective Conversion | Direct digital control, automatic completion |

4.5 | Objective magnification | Measure 40X Observe 10X |

4.6 | Digital display resolution | 0.03μm |

4.7 | Sample size | Maximum height 90mm |

4.8 | photography channel | Have |

5 | Design Powered | AC220V±10%、50Hz、60W |

6 | Display content | d1, d2, HV, (HK, HRC conversion), F, T, COUNT status |

Coating wear resistance testing equipment

Equipment introduction: Coating friction and wear tester is mainly used for the measurement of wear resistance and friction coefficient of various thin film materials. Schematic diagram of the structure of the coating wear tester

Performance parameters

| Numbering | project | technical parameter |

1 | name | Coating friction and wear tester |

2 | model | POD-1-AUTO |

3 | Equipment structure | |

3.1 | Dimensions | 400 (L )mm×2300 (W)mm×205 (H) mm |

3.2 | Cantilever length | Cantilever length: 310mm, accuracy: ±0.01% |

3.3 | control computer | Dell, commercial grade, hard disk 160G, 17" LCD, standard RS232 configuration |

3.4 | motor | Panasonic servo motor, model: MHMA102P1H, rated speed: 2000r/min |

3.5 | load weight | Place of Origin: Ningbo Huitong Weight, Material: Stainless Steel, Accuracy: E2 Grade |

3.6 | load range | Range: 0.2-50N |

4 | Design Powered | AC 220V±5%,50HZ,100VA |

5 | Environmental requirements | Temperature:<40℃; Humidity: <80%RH |

6 | Control System | |

6.1 | Control method | Computer automatic control, man-machine interface operation |

6.2 | operating system | Based on WINDOWS 2000 and above operating systems |

6.3 | Motor Control Driver | Panasonic Drive, Model: MBDDT22100032, Rack Model: Type B |

6.4 | Cantilever beam pressure sensor | Original from Japan NMB, Model: C2G1-10K, Accuracy: ±0.02%F•S |

6.5 | Computer measurement and control software | Independent research and development |

6.6 | Operation control board | Accuracy class 1 |

6.7 | Data collection | Acquisition rate: 10 times/second; standard RS232 port |

7 | Software function | |

7.1 | Image output | The test curve graph can be displayed in real time; any time period can be specified to observe the curve |

7.2 | real-time acquisition | Simultaneous acquisition of test force-time data; real-time acquisition of load sensor signals; |

7.3 | data conversion | Min/Sec time unit can be switched; load N/kgf unit can be switched |

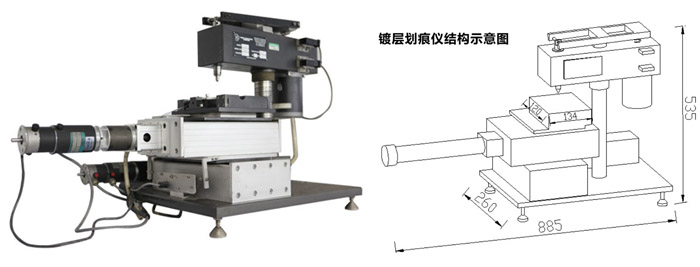

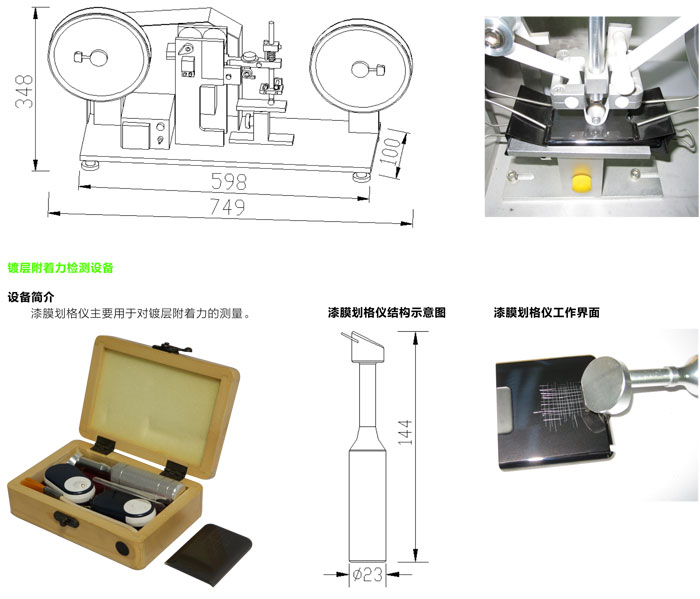

Coating adhesion testing equipment

Equipment introduction: Coating scratch tester is mainly used for the measurement of film/base critical adhesion, scratch depth and scratch width of various thin film materials.

Performance parameters

| Numbering | project | technical parameter |

1 | name | High Load Scratch Tester Revetest (1N - 200N) |

2 | model | |

3 | Equipment structure | |

3.1 | Dimensions | 885(L)×260(W)×535(H)mm |

3.2 | XY table | 70mm X 20mm |

3.3 | scratched needle | Material: diamond |

3.4 | acoustic emission sensor | CMS original acoustic emission sensor |

4 | Forward load range | 0.5-200N |

5 | load resolution | 3mN |

6 | maximum friction | 200N |

7 | Friction Resolution | 3mN |

8 | Maximum scratch length | 70mm |

9 | Maximum scratch depth | 1mm |

10 | Equipment Design Standards | Compliant with international industry standards ASTM, C1624, EN 1071 |

MAMS coating inspection equipment

Coating hardness testing equipment

Equipment introduction: Electric pencil hardness tester is mainly used to measure the surface hardness and scratch resistance of coating. Structure diagram of electric pencil hardness testing machine

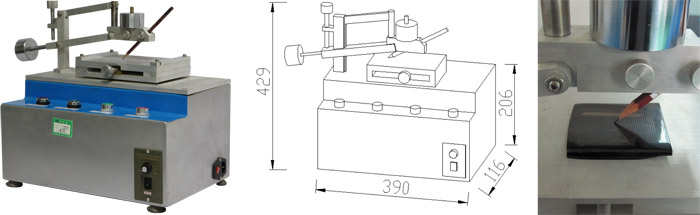

Coating wear resistance testing equipment

Equipment introduction: The RCA paper bag friction tester is mainly used to measure the wear resistance of hardware shells, P.D.A laptops and various surface coating products.

Schematic diagram of the structure of the RCA paper tape friction tester:

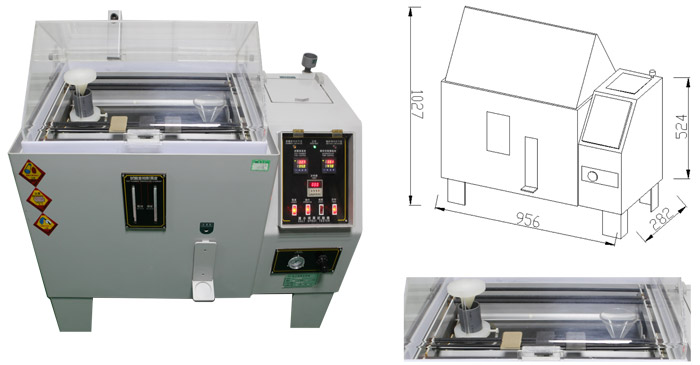

Coating salt spray resistance testing equipment

Equipment introduction: Salt spray testing machine is mainly used for testing the corrosion resistance of various coatings. Schematic diagram of the structure of the salt spray test machine

Coating alcohol testing equipment

Equipment introduction: The abrasion resistance tester is mainly used for the solvent resistance test of each medium coating. Structure diagram of alcohol abrasion tester