Contact Us

Tel: 0755-29450980

Fax: 0755-29450871

E-mail: kingmag@king-mag.com.cn

Address: Building B, Bafang Zhigu, Junzibu Community, Guanlan Street Office, Longhua District, Shenzhen

GIC nano-amorphous self-lubricating coating

Scope of application

Automotive Engines & Spare Parts Cutting Tools & Moulds Easy Wear Parts for Machinery Oil-Free Lubricating Spare Parts for Textile Industry

Moving parts of equipment operating in wet environments Parts for the food industry

Rain and snow fields Parts for die-forming equipment Parts requiring a low coefficient of friction

Applications

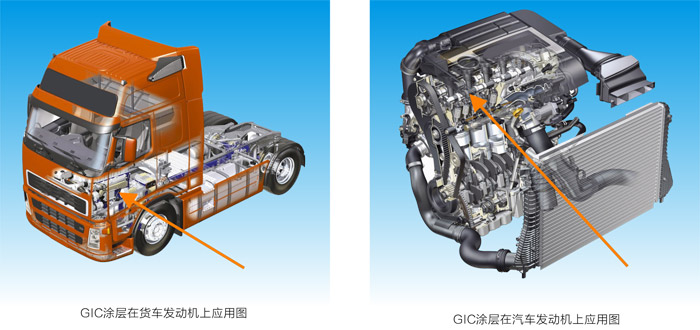

Applications in the automotive industry

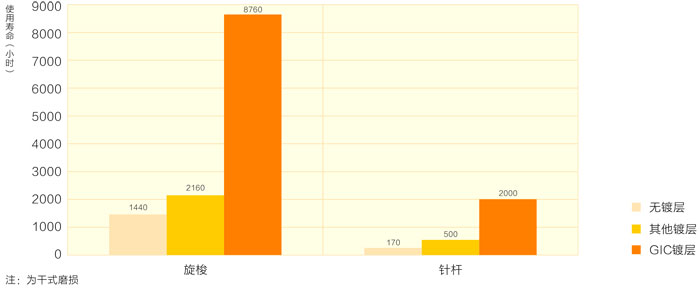

Plunger bench test for fuel injection system applications

project | Test category | |

1500 hours plunger bench test | 300 vehicle tests | |

With GIC coating | There is no problem in the test, the matching clearance is good, and the operation is normal | 1% wear does not occur within the set range |

No GIC coating | Parts are often worn during the test, and the fitting clearance is poor | There is a 3% chance that accessories will be unavailable due to wear and tear |

Tappet bench experiment of engine system

project | 500 hours bench test |

With GIC coating | The end face wears evenly, the parts have no notch, and the end face roughness is about 0.3 |

No GIC coating | There is uneven wear on the end face, some parts have gaps, and the end face roughness is about 0.5 |

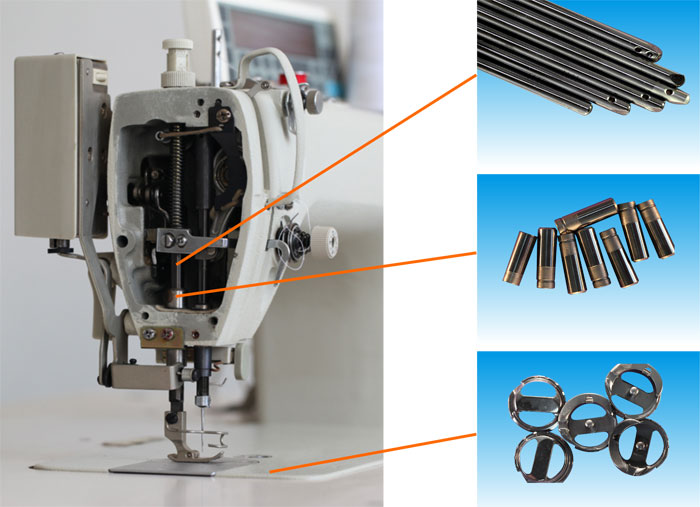

At the same time of the rapid development of the high-speed sewing machine industry, the problem of oil leakage and wear resistance has become a bottleneck restricting the development of the industry. The application of GIC coating on high-speed industrial sewing machine products effectively solves this problem and realizes oil-free lubrication and super wear resistance. dual performance.

Other Sewing Machine Coated Parts