Contact Us

Tel: 0755-29450980

Fax: 0755-29450871

E-mail: kingmag@king-mag.com.cn

Address: Building B, Bafang Zhigu, Junzibu Community, Guanlan Street Office, Longhua District, Shenzhen

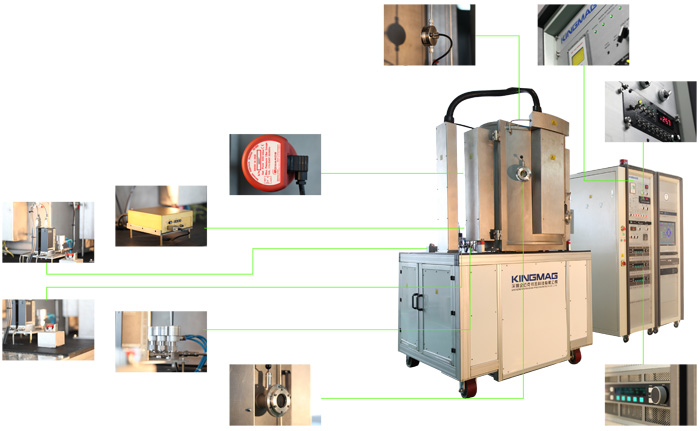

Equipment manufacturing

Coating equipment

At present, the company has independently designed and developed two series of MSIP and MAMS six categories of new nano-amorphous thin film material preparation equipment and various types of thin film performance testing equipment.

MSIP coating equipment

Features

A fully automatic coating control program under the windows operating system controls the film growth process accurately in all directions;

B The whole equipment adopts the best high-precision control components to accurately control the composition gradient inside the film;

C The self-developed magnetron is precisely matched with the well-designed coating control program, and the uniformity deviation is not more than 1%;

D low temperature deposition, the working temperature is controlled within the temperature that induces the change of the matrix structure;

E Good quality uniformity, coating thickness deviation of all positions in the furnace is less than 5%;

F Good repeatability, the thickness deviation of coatings prepared by different heats in the same process is not more than 5%;

G Complete supporting facilities: years of practical experience have accumulated to provide a complete set of solutions for industrial applications;

H Excellent service: provide nanny-style after-sales service and lifetime technical support;

Type

| Configuration/Model | vacuum system | Furnace structure | control method |

| MSIP850/4-S | Three-stage vacuum pump: Edwards original diffusion pump + Roots pump + mechanical pump | side opening | Full manual mechanical control |

| MSIP850/4-Pro | Three-stage vacuum pump: Edwards original diffusion pump + Roots pump + mechanical pump | side opening | computer program control |

| MSIP850/4-Ultra | Three-stage vacuum pump: Edwards original diffusion pump + Roots pump + mechanical pump | side opening | Computer program control + manual control |

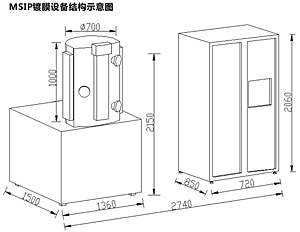

Related technical parameters

| serial number | Item Device model | CFMS850/4-Ultro | CFMS850/4-Pro | CFMS850/4-S |

1 | Overall dimensions (dimensions after installation: length × width × height) | 4.0×4.0×2.6m | 4.0×4.0×2.6m | 4.0×4.0×2.6m |

1.1 | host | 1.5×1.4×2.4m | 1.5×1.4×2.4m | 1.5×1.4×2.4m |

1.2 | Control cabinet | 2.0×0.8×2.2m | 1.0×0.8×2.2m | 1.0×0.8×2.2m |

1.3 | refrigerator | 1.0×0.7×2.0m | 1.0×0.7×2.0m | 1.0×0.7×2.0m |

2 | rated power | 50KW | 45KW | 45KW |

3 | Rated voltage | 400V(±10%) | 400V(±10%) | 400V(±10%) |

4 | Furnace structure | |||

4.1 | The actual size of the furnace body (diameter × height) | Φ700×1000mm | Φ700×1000mm | Φ700×1000mm |

4.2 | Effective size of oven cavity | Φ500×700mm | Φ500×700mm | Φ500×700mm |

4.3 | Furnace door opening method | side opening | side opening | side opening |

4.4 | Furnace cooling method | water cooling | water cooling | water cooling |

4.5 | Furnace design allows maximum load | 500Kg | 500Kg | 500Kg |

4.6 | Diameter of rotary table | 450mm | 450mm | 450mm |

4.7 | The design of the auto-rotating chuck table allows the maximum load | 100Kg | 100Kg | 100Kg |

4.8 | Quantity of auto transfer card table | 6 | 6 | 6 |

4.9 | target number | 4 | 4 | 4 |

4.10 | Target size (length × width) | 725×175mm | 725×175mm | 725×175mm |

4.11 | Number of high-precision temperature measuring thermocouples | 2 | none | none |

4.12 | automatic fender | Optional | none | none |

4.13 | Number of furnace observation windows | 3 | 3 | 3 |

5 | Sputtering power supply | |||

5.1 | 6KW Advanced Energy PNCL Target power supply (accuracy ±0.01A) | 4 units | 4 units | 4 units |

5.2 | 10KW Advanced Energy PNCL Bias power supply (accuracy ±1V) | 1 set | 1 set | 1 set |

6 | vacuum system | |||

6.1 | Mechanical Pump (Original BOC Edwrds Pump) | E2M40 | E2M40 | E2M40 |

6.2 | Roots pump (BOC Edwrds original pump) | EH500 | EH250 | EH250 |

6.3 | Diffusion pump (BOC Edwrds original pump) | B35032978 | B35032978 | B35032978 |

6.4 | High vacuum gauge | WRG-S | WRG-S | WRG-S |

6.5 | Foreline vacuum gauge | APGX-M-NW16 | APGX-M-NW16 | APGX-M-NW16 |

6.6 | Vacuum connection lock | IS16K | IS16K | IS16K |

6.7 | Design coating actually vacuum degree | 4.0×10-3Pa | 4.0×10-3Pa | 4.0×10-3Pa |

6.8 | Ultimate vacuum | 1.4×10-4Pa | 3.4×10-4Pa | 3.4×10-4Pa |

6.9 | Cold air leak rate | 2.0×10-1Pa/h | 3.0×10-1Pa/h | 3.0×10-1Pa/h |

6.10 | Vacuuming time (to reach the initial vacuum degree of coating) | <30min | <50min | <50min |

7 | Atmosphere Control System | |||

7.1 | Multi-channel gas flow controller ((BOC Edwrds original pump)) | 4 channels | 2 channels | 2 channels |

7.2 | Gas mass flow controller (original from American MKS, 0.1SCCM) | 3 | 2个 | 2个 |

7.3 | OEMTM Reactive Gas Controller Grade Piezo Valves | Generic option | Generic option | Generic option |

8 | Control System | |||

8.1 | control method | Computer/manual dual mode control | computer control | Full manual control |

8.2 | PLC (German Vipa original, military grade) | Have | Have | Have |

8.3 | Industrial Control Computer (Dell, Military Grade, DVD Burning) | Have | Have | none |

8.4 | Operating system (Chinese version of Windows Xp Pro) | Have | Have | none |

8.5 | Remote control (with PC Anyway software level random Modem) | Have | Have | none |

8.6 | USP uninterruptible power supply (1500W·H) | Have | Have | none |

9 | Software features | |||

9.1 | Real-time control/data acquisition function | Have | Have | none |

9.2 | Create various process files under the window/automatically control the process flow | Have | Have | none |

9.3 | Self-contained database/process library/maintenance package/online help/alarm/fault analysis | Have | Have | none |

9.4 | Administrator privilege level/user password setting function | Have | Have | none |

10 | Fully manual operation | Have | Have | Have |

11 | Shelf life | 1 year | 1 year | 1 year |

Types of coatings that can be prepared

Type of coating | Plating name | Application field |

hard coating | NGH series nano gradient super hard coating | All kinds of high-speed steel, carbide cutting tools and various molds, micro-drilling gongs for PCB |

TiAlN super hard coating | Suitable for all kinds of metal cutting milling cutters | |

TiN super hard coating | Suitable for all types of taps | |

Self-lubricating coating | Graphit-IC self-lubricating coating | Suitable for all kinds of precision metal products with wear reduction requirements |

MoST self-lubricating coating | Suitable for all kinds of precision metal products with wear reduction requirements |

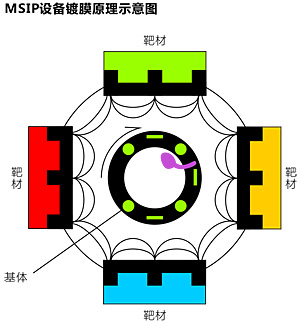

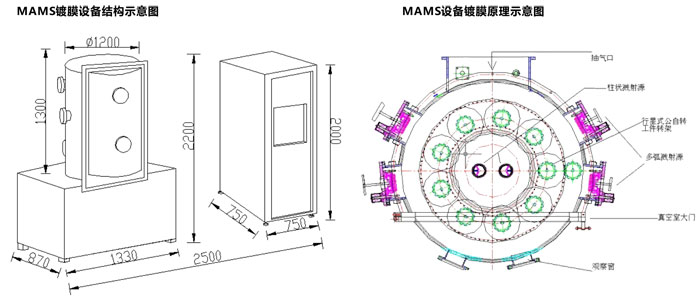

MAMS coating equipment

Perfect match: Magnetron sputtering and multi-arc sputtering technology are organically integrated, making the best of strengths and avoiding weaknesses to achieve coating;

Advanced technology: The coating process design is flexible, and a variety of color films can be prepared to meet the needs of product design;

Easy to operate: The equipment operation interface is simple, and the automatic "fool-like" operation can effectively avoid human errors;

Uniform quality: using the best components, stable operation, precise control, and strong process repeatability;

Strong adaptability; strong adaptability, able to meet the processing needs of various industries and products;

Perfect system: The system is perfect, providing a full range of pre-sale, in-sale and after-sale support.

Type

| Configuration/Model | vacuum system | Cavity size | control method |

MAMS800SA | Two-stage vacuum pump: equipped with diffusion pump + mechanical pump | ψ800×1000 | Full manual control |

MAMS 1000SA | Two-stage vacuum pump: equipped with diffusion pump + mechanical pump + maintenance pump | ψ1000×1200 | PLC program control + full manual control |

MAMS 1200SA | Three-stage vacuum pump: diffusion pump + Roots pump + mechanical pump + maintenance pump | ψ1200×1200 | PLC program control + full manual control |

technical parameter

| serial number | Item/Device Model | DMS800AS | DMS1000AS | DMS1200AS |

1 | Overall dimensions (dimensions after installation: length x width x height) | 5x4x2.2m | 5x4x2.2m | 6x5x2.2m |

1.1 | host | 4×1.2×2.2m | 4×1.5×2.2m | 4×2×2.2m |

1.2 | Control cabinet | 1×0.8×2m | 1×0.8×2m | 1×1.6×2m |

2 | Refrigerator + circulating water tank | 5×2×1.5m | 5×2×1.5m | 5×2×1.5m |

3 | rated power | 35KW | 45KW | 65KW |

4 | Rated voltage | 380V(+/-10%) | 380V(+/-10%) | 380V(+/-10%) |

5 | Furnace structure (SUS304 double layer with water cooling jacket) | |||

5.1 | The actual size of the furnace cavity (diameter × height) | Φ800×1000mm | Φ1000×1100mm | Φ1200×1300mm |

5.2 | Effective size of oven cavity | Φ600×750mm | Φ800×850mm | Φ1000×1000mm |

5.3 | Furnace door opening method | side opening | side opening | side opening |

5.4 | Furnace cooling method | water cooling | water cooling | water cooling |

5.5 | Diameter of rotary table | Φ400mm | Φ600mm | Φ800mm |

5.6 | Furnace design allows maximum load | 150Kg | 180Kg | 200Kg |

5.7 | Quantity of auto transfer card table | ≥6 | ≥9 | ≥12 |

5.8 | Self-loading pallet design allows maximum load | 25Kg | 50Kg | 80Kg |

5.9 | target number | 6+1 | 6+2 | 6+2 or 4 |

5.10 | Target size (arc target) | Φ100×40mm | Φ100×40mm | Φ100×40mm |

5.11 | Target size (cylindrical target) | Φ70×900mm | Φ70×1020mm | Φ70×1020mm |

5.12 | Number of high-precision temperature measuring thermocouples | 2 | 2 | 2 |

5.13 | Vacuum Chamber Liner | 2 | 2 | 2 |

5.13 | Number of furnace observation windows | 2 | 2 | 2 |

6 | Sputtering power supply | |||

6.1 | 2x6KW 150A DC inverter sputtering power supply (control precision ±0.5A) | 3 units | 3 units | 3 units |

6.2 | 30KW intermediate frequency sputtering power supply (control accuracy ±1V) | 1 set | 1 set | 2+ |

6.3 | 20KW inverter pulse bias power supply (control accuracy ±1V) | 1 set | 1 set | 1 set |

7 | vacuum system | |||

7.1 | mechanical pump | 1 set | 1 set | 1 set |

7.2 | Roots pump | none | none | 1 set |

7.3 | Diffusion Pump | KT400 | KT500 | KT600 |

7.4 | High vacuum gauge (ionization gauge) | ZJ-27 | ZJ-27 | ZJ-27 |

7.5 | Foreline Gauge (Thermocouple Gauge) | ZJ-51 | ZJ-51 | ZJ-51 |

7.7 | Design coating initial vacuum degree | 6.0×10-3Pa | 6.0×10-3Pa | 6.0×10-3Pa |

7.8 | Ultimate vacuum | 3.0×10-4Pa | 3.0×10-4Pa | 3.0×10-4Pa |

7.9 | Cold air leak rate | 2.0×10-1Pa/h | 3.0×10-1Pa/h | 3.0×10-1Pa/h |

7.10 | Evacuation time (the product enters the furnace to the start of vacuum coating) | ﹤30min | ﹤30min | ﹤30min |

8 | Atmosphere Control System | |||

8.1 | Multi-Channel Gas Flow Controller | 3 channels | 3 channels | 3 channels |

8.2 | Gas Mass Flow Controller | 3 | 3 | 3 |

9 | Control System | |||

9.1 | Control method (optional) | Automatic/manual dual mode control | Automatic/manual dual mode control | Automatic/manual dual mode control |

9.2 | PLC (Original from MITSUBISHI, Japan) | Have | Have | Have |

9.3 | touch screen | Have | Have | none |

10 | Software features | |||

10.1 | Real-time control/data acquisition function | Have | Have | none |

10.2 | Create various process files under the window/automatically control the process flow | Have | Have | none |

10.3 | Self-contained database/process library/alarm/fault prompt analysis | Have | Have | none |

11 | Fully manual operation | Have | none | Have |

12 | Warranty | one year | one year | one year |

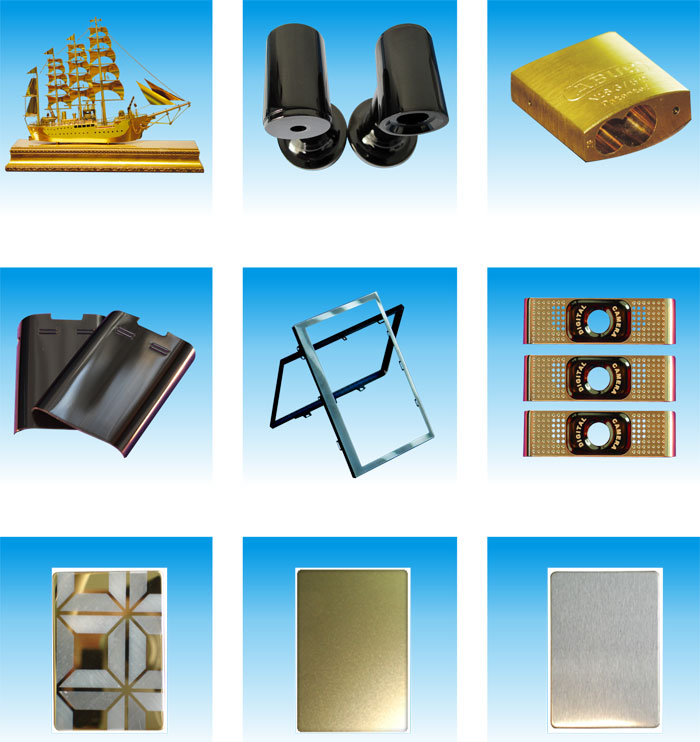

Types of coatings that can be prepared

| Type of coating | Plating name | Application field |

decorative coating | TiN、ZrN、Gold series | Various types of blades, tableware, locks, bathroom, hardware sanitary ware, ceramics, glass and other hardware parts |

TiC, CrC black series | Watches and clocks, mobile phones, digital product shells, lighting bathrooms, spectacle frames and other hardware products | |

TiCN, TiAlN brown color | Watches and clocks, mobile phones, digital product shells, lighting bathrooms, spectacle frames and other hardware products |